| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : ROSCHEN

Model Number : BQ NQ HQ PQ NQ3 HQ3 PQ3

Certification : ISO

Place of Origin : CHINA

MOQ : 1 pcs

Price : Negotiate

Supply Ability : 100000000 pcs

Packaging Details : Steel bundle

Payment Terms : T/T

Delivery Time : 5 - 8 working days

Function : well drilling rods

Taper Degree : 12,4,7,6

Barrel : Diamond Drilling Coring Barrel

Applicable Industries : Construction works , Energy & Mining

Diameter : 5 cm

Surface Treatment : Heat treatment

Processing Type : Forging,Casting

Connection : Mayhew API thread

Series No : hollow metal rod

Welding Technology : friction welding

Mining : Australia Mining

Drill Rod Sells : drill rod stock

Yield Strength : ≥ 600 MPa

Features : High Precision

Drill Rod Supplier : Rotary Drill Rods manufacturer

Wireline Drilling Rods for Geothermal & Diamond Core Drilling

Drill Rods

Available in industry-standard B, N, H, and P-HD sizes, ROSCHEN drill rods come in both 1.5m and 3m lengths to suit your drilling requirements. We only offer bulk in containerized supply options, with various container weights and sizes available.

Geothermal & Core Drilling Rods

At ROSCHEN, we've combined industry-leading expertise, premium products, and advanced techniques to deliver a unique offering in exploration drilling. Our standard wireline rods are the global benchmark for wireline drilling—trusted and proven worldwide. Through innovative engineering and state-of-the-art manufacturing, ROSCHEN meets the evolving demands of the market with precision and performance.

Wireline Drilling Rods Features:

. Global Standard

. Precision Engineering

. Market-Driven Design

. Improved Borehole Stability

Advantages:

Premium Precision Alloy Tubing

1. Manufactured from seamless high-grade alloy steel.

2. Precisely controlled concentricity, straightness, and treatment.

3. Stress-relieved to minimize unwanted bending forces.

High-Performance Threading

1. Tapered, coarse threads for quick make-and-break.

2. Load efficiency of 30–35% supports standard drilling loads.

3. Engineered for smooth engagement and lasting durability.

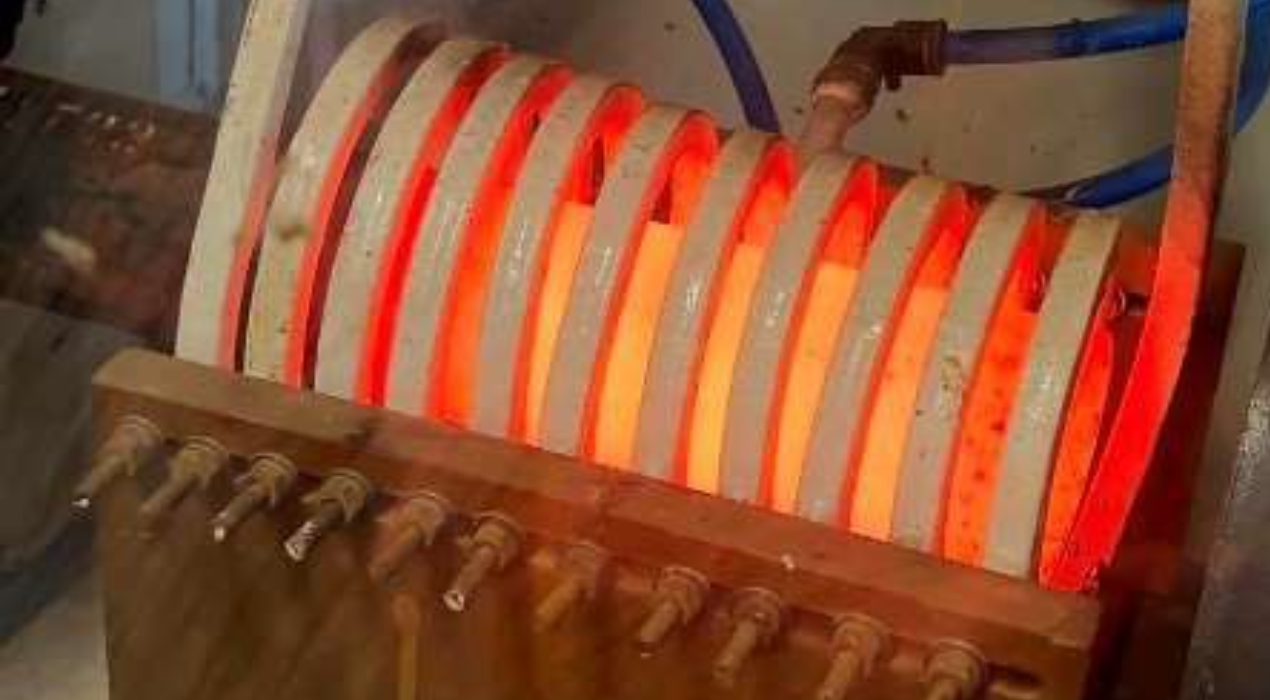

Thru-Wall Heat Treatment

1. Delivers 140% material strength over untreated steel.

2. Treated box and pin threads extend operational lifespan.

3. Boosts tensile and yield strength for deeper drilling.

Optimized Joint Designing

1. Double-shouldered joints minimize fluid loss.

2. Built-in rod weight ensures proper tension distribution.

3. Enhances overall drill string stability and performance.

Metric Length of Drilling Rods

| SIZE | Length (m) | OD (mm) | ID (mm) | WEIGHT (KG) | THREAD PITCH (mm) | PIN LENGTH (mm) | CONTENT (1/100m) |

| BQ | 1.5 M | 55.6 | 46.1 | 9 | 8.5 | 44.45 | 167.00 |

| BQ | 3.0 M | 55.6 | 46.1 | 18 | 8.5 | 44.45 | 167.00 |

| NQ | 1.5 M | 69.9 | 60.3 | 11.6 | 8.5 | 44.45 | 286.00 |

| NQ | 3.0 M | 69.9 | 60.3 | 23.1 | 8.5 | 44.45 | 286.00 |

| HQ | 1.5 M | 88.9 | 77.8 | 17.1 | 8.5 | 44.45 | 475.00 |

| HQ | 3.0 M | 88.9 | 77.8 | 34.2 | 8.5 | 44.45 | 475.00 |

| PQ | 1.5 M | 114.3 | 101.6 | 25.4 | 10.2 | 62.8 | 811.00 |

| PQ | 3.0 M | 114.3 | 101.6 | 50.7 | 10.2 | 62.8 | 811.00 |

Rod Bundle Details

| SIZE | Length (m) | # Rod per Bundle | Length (mm) | Width (mm) | Height (mm) | Wt./Bundle (mm) | Bundles/Container (40ft HC) |

| BQ | 1.5 M | 19 | 1580 | 292 | 254 | 181 | 126 |

| BQ | 3.0 M | 19 | 3080 | 292 | 254 | 355 | 63 |

| NQ | 1.5 M | 19 | 1580 | 368 | 330 | 239 | 100 |

| NQ | 3.0 M | 19 | 3124 | 368 | 330 | 453 | 52 |

| HQ | 1.5 M | 19 | 1580 | 470 | 406.4 | 343 | 60 |

| HQ | 3.0 M | 19 | 3080 | 470 | 406.4 | 674 | 35 |

| PQ | 1.5 M | 7 | 1580 | 356 | 320 | 190 | 104 |

| PQ | 3.0 M | 7 | 3080 | 356 | 320 | 370 | 52 |

SPECIFICATIONS DATA

| SPECS | BQ | NQ | HQ | PQ |

| OD | 55.60 mm | 69.90 mm | 88.90 mm | 114.30 mm |

| ID (Box Shoulder) | 46.00 mm | 60.30 mm | 77.80 mm | 101.60 mm |

| Wall thickness | 4.90 mm | 4.80 mm | 5.55 mm | 6.35 mm |

| Rod/Hole Annulus Volume | 0.40 l/m | 0.68 l/m | 1.05 l/m | 1.54 l/m |

| Recommended Max Depth | 1500 m | 2000m | 1500 m | 1500 m |

| Recommended Max Pullback | 112 kN | 140 kN | 326 kN | 352 kN |

| Recommended Max Drilling Torque | 759 Nm | 1257 Nm | 2503 Nm | 5438 Nm |

| Min Yield Strength (joint) | 1070 MPa | 1070 MPa | 1070 MPa | 1070 MPa |

| Min Tensile Strength (joint) | 1200 MPa | 1200 MPa | 1200 MPa | 1200 MPa |

| Collapse Pressure | 114 MPa | 81 MPa | 69 MPa | 55 MPa |

Max Container Weight Per Region

| DESTINATION | 20' Standard | 40' Standard |

| Albania, Tirana | 21 700 | 24 204 |

| Australia, Melbourne, Freemantle | 16 000 | 19 400 |

| Brazil, Santos | 22 000 | 23 000 |

| Colombia, Cartagena | 22 000 | 23 000 |

| Chile, Santiago, San Antonio | 22 000 | 23 000 |

| Domonican Republic, Rio Haina | 21 700 | 23 000 |

| Finland, Helsiniki | 21 700 | 24 404 |

| Germany, Nurenburg | 21 700 | 24 404 |

| Guatemala, Guatemala City | 18 800 | 20 000 |

| Holland | 21 700 | 24 404 |

| Norway, Oslo | 21 700 | 24 404 |

| Pakistan, Karachi | 21 700 | 24 404 |

| Peru, Callao | 22 000 | 24 404 |

| Russia, St Petersburg, Moscow | 21 700 | 24 404 |

| South Africa, Cape Town | 21 500 | 24 404 |

| Sweden, Helsingborg | 21 700 | 24 404 |

| Turkey, Izmir, Istanbul | 21 500 | 24 404 |

| UK, Rowley Regis | 21 700 | 24 404 |

| Ukraine, Odessa | 21 700 | 24 404 |

Compatibility Notice

To ensure optimal performance and longevity of your drill rods, ROSCHEN recommends using only ROSCHEN manufactured rods within each drill string. While rods from other manufacturers may appear similar in material, thread design, or manufacturing process, variations in dimensions and tolerances may affect compatibility and could lead to reduced performance or premature wear.

|

|

Wireline Drilling Rods for Geothermal & Diamond Core Drilling Images |